5 Finest Online Training Trends in the Manufacturing Industry

The manufacturing industry, though one of the largest industries in the world, has a population of people who do not have a high level of technical education. And the employee turnover is quite high. The industry needs to continually design, develop, and distribute Safety Guidelines & SOPs for shop floors, logistics, and storage. The key is to adopt training and development strategies, for training unskilled employees. With proper training, there will be a boost in the manufacturer’s productivity, a decrease in employee turnover, and fill the talent gaps. This blog talks about five online training trends that work very well for the manufacturing industry.

Wondering What are the Best Online Training Trends in the Manufacturing Industry?

Well, here are 5 finest ones -

- Microlearning

- Collaborative learning

- Video-based learning

- Gamification

- Simulation-based learning

5 Online Training Trends in the Manufacturing Industry

1. Microlearning

Today’s learners have limited attention spans. Sitting through lengthy classroom sessions is not viable. However, considering the various kinds of training programs needed for the workers, microlearning is a good solution. Workers use sophisticated machinery that is complex to understand. Microlearning produces immediate results and it aligns perfectly well with the ever-changing industry standards. Microlearning is also budget-friendly, making it a practical option for training. Microlearning works best for the following kinds of training programs:

- First aid training

- Basic OSHA training

- Industrial safety training

- Diversity training

- Sexual harassment training

- Training to prevent violence

- Good Manufacturing Practices

- Supply Chain Management

- Manufacturing Processes and Quality Standards

2. Collaborative Learning

The collaborative learning idea is a profoundly intelligent methodology as in this technique, the learner learns through learning programs as well as through connecting with peers; learners are in part or infrequently in charge of each other’s progress. Collaborative learning can be conducted either offline or online. Mutual ideas, skills, and experiences of learners engaged in the process are shared.

With collaborative learning, employees are engaged in learning and working at the same time. They are more deeply connected and participate actively in honing their knowledge and skills, which becomes the biggest factor in retaining what is learned. For example, junior machine operators can readily get their doubts on machine technicalities clarified by senior operators, through discussion forums.

→ Download eBook Now: The State of Learning 2023 and Beyond

3. Video-Based Learning

One of the most important aspects of learning is the exchange of information. In a passive learning environment, it is a one-way affair. However, the need to capture a learner’s attention is crucial. Videos have the potential to turn learning experiences into a positive exchange of knowledge. Using video-based learning for manufacturing employees can inject a visual element into teaching complex concepts. Videos are an alternative to using training manuals that contain nothing but black print on white paper. For example, to train employees on safety, illustrating through a video is a good idea. It will help learners understand the hazards better.

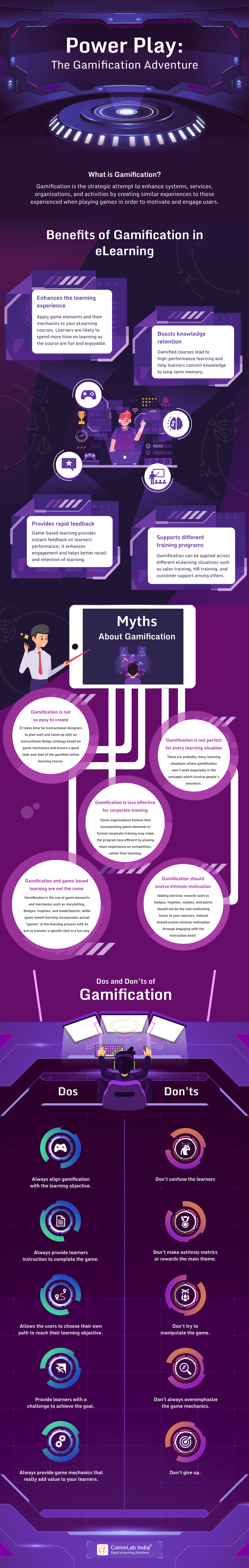

4. Gamification

“All work and no play makes Jack a dull boy.”

The fact is engaged employees are more productive. The concept of applying game mechanics for training employees in the manufacturing sector is beneficial. It provides enhanced learner experience and improved productivity. Siemens AG, a German conglomerate company, deployed Plantsville, a factory-based game platform to showcase products and solutions for industry and infrastructure.

The online game simulates a plant manager’s experience – challenging players to increase the productivity, sustainability, and overall health of an industrial plant in Siemens. When employed correctly, gamification is successful in motivating employees, creating healthy competition among teams, and a fun work environment.

5. Simulation-Based Learning

Simulations offer an alternative real-world experience to learners, making them participate and engage actively in their jobs. The diversified manufacturing industry requires employees to perpetually work on their existing skills or learn new skills. At times like these, simulations in eLearning help build a virtual environment where learners can exercise these skills in a risk-free environment. Most of the processes in the manufacturing industry are automated and the same must be replicated in the training.

For instance, in a manufacturing plant when there is a need to train technicians on operating a piece of new complex machinery, letting new employees handle it is risky. In such circumstances, a simulation replicates the steps to operate the machine and also lets the user practice the steps required to operate it. This can save time and bring down the training cost drastically.

Wrapping Up!

Given that the manufacturing industry is relentlessly evolving, the need for training is constant. Utilizing these trends for employee training will ensure learning is effective in delivering the expected outcomes, for a long time. To help you understand what's trending right now or what will be the state of learning in the coming days, here’s a free eBook for you. Download it now!

Editor’s note: This post was originally published in February 2018 and has been updated for comprehensiveness.

![eLearning Trends for 2021: What Should You Pick & Why? [Infographic]](https://blog.commlabindia.com/hubfs/Imported_Blog_Media/elearning-trends-corporate-training-info.jpg)